Leave Your Message

In the dynamic realm of construction and engineering, the effectiveness of a project often hinges on the selection and utilization of the right tools and components. One such critical element is the CTV Chain Isolator, a device designed to enhance safety and performance in various applications. Whether it's in the context of civil engineering, manufacturing, or any project involving chain-driven mechanisms, understanding how to effectively implement a CTV Chain Isolator can drastically improve operational efficiency and mitigate risks.

This article aims to provide the top 10 essential tips for utilizing the CTV Chain Isolator in your projects. From installation techniques to maintenance best practices, each tip will be grounded in a practical approach to ensure optimal functionality. By mastering these techniques, project managers, engineers, and technicians can leverage the full potential of the CTV Chain Isolator, ensuring that their operations are not only safe but also highly efficient. As we delve into these tips, you'll discover how a better understanding of this critical component can lead to measurable improvements in your project's overall success.

Chain isolators play a crucial role in various engineering and construction projects by providing effective solutions for mitigating vibrations and interruptions in mechanical systems. Understanding their key features and benefits can significantly enhance the performance and longevity of your projects. CTV chain isolators are designed to isolate dynamic loads while offering rigidity and stability. This ensures that machinery and equipment operate smoothly without transferring excessive vibrations, which can lead to wear and tear over time.

When incorporating CTV chain isolators into your projects, consider these tips for effectiveness. First, assess the specific vibration frequencies and load requirements of your application. This information is vital in selecting the appropriate isolator, ensuring that it can handle the unique demands of your system. Second, installation accuracy is paramount. An improperly aligned isolator can lead to compromised performance; therefore, take the time to ensure that each unit is positioned correctly. Lastly, regular maintenance checks are essential. Periodic inspections help identify any signs of wear and ensure that the isolators function as intended over time.

By focusing on the unique features and advantages of CTV chain isolators, you can leverage their capabilities to enhance the efficiency and resilience of your projects. Incorporating these tips will not only optimize performance but also contribute to the overall durability of your systems.

Installing CTV chain isolators effectively is crucial for optimizing the performance and longevity of your projects. One of the best practices is to ensure proper alignment during installation. Misalignment can lead to uneven load distribution, resulting in premature wear or failure of the isolator. According to a report by the American Society of Mechanical Engineers, correctly aligned isolators can minimize dynamic loads by up to 30%, enhancing operational efficiency significantly.

Another important aspect is to consider environmental factors such as temperature and vibration in your installation strategy. For instance, studies indicate that operating in extreme temperatures without adequate insulation can reduce the isolator's efficiency by nearly 15%. It is recommended to conduct a thorough site assessment prior to installation, considering potential vibrations that may affect the isolator. The vibration analysis can lead to the selection of isolators that provide the best performance under specific project conditions.

Lastly, regular maintenance and inspection should not be overlooked. A maintenance report from the National Institute of Standards and Technology shows that routine checks and timely replacements of worn components can extend the life of chain isolators by 40%. Implementing a systematic inspection schedule ensures that the isolators operate within optimal parameters, keeping projects on track and reducing unexpected downtimes.

Choosing the right CTV chain isolator for your project is crucial to ensure optimal performance and safety. According to a report by the International Association of Electrical Inspectors, improper sizing can lead to significant inefficiencies, increasing operational costs by as much as 15%. When evaluating the specifications of a CTV chain isolator, it is essential to consider factors such as load requirements, environmental conditions, and the specific use case in your project. A miscalculation in sizing might not only compromise the system's efficiency but could also pose risks related to equipment damage or even safety hazards.

For a well-rounded approach, industry standards suggest conducting a thorough load analysis before selecting an isolator. This analysis should encompass peak operational loads and potential fluctuations during use. The National Electrical Manufacturers Association highlights that a properly sized chain isolator can enhance system reliability and performance, reducing downtime and maintenance needs, which in turn can save up to 20% in operational costs over time. By carefully considering these criteria, engineers and project managers can ensure that they select an isolator that not only meets current demands but also accommodates future scalability needs.

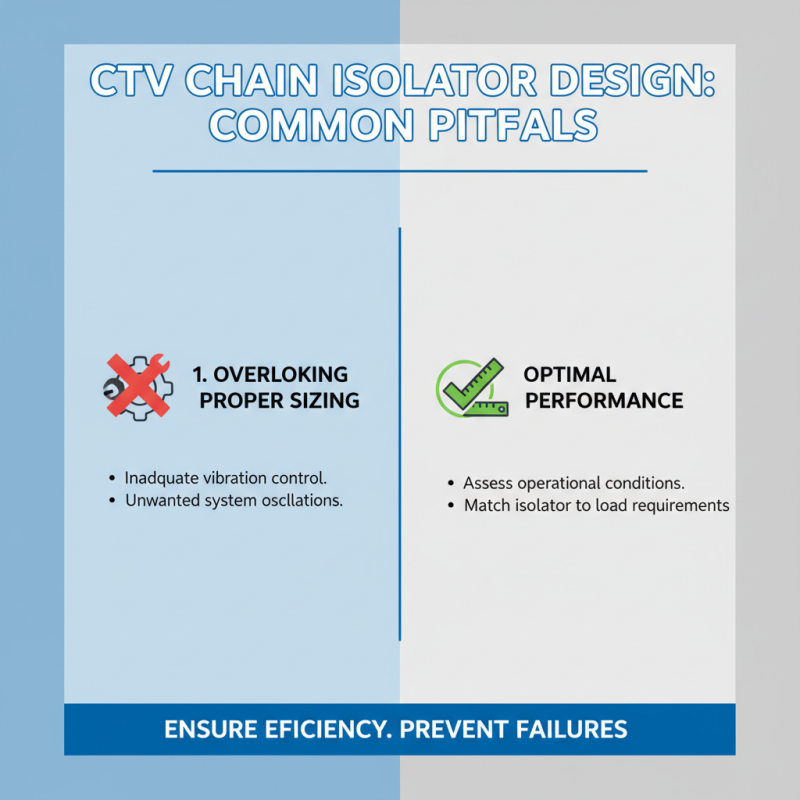

When utilizing CTV chain isolators in design, there are several common pitfalls that can hinder the effectiveness of your projects. One significant mistake is overlooking the importance of proper sizing. Choosing an inadequately sized isolator can lead to insufficient vibration control, resulting in the transmission of unwanted oscillations throughout the system. It's essential to assess the operational conditions and select isolators that align with the specific load requirements to ensure optimal performance.

Another frequent error is neglecting installation guidelines. CTV chain isolators must be positioned correctly to maximize their isolation properties. Improper alignment can lead to uneven loading, which may cause premature wear or failure of the isolators. Additionally, overlooking the need for routine maintenance and inspection can lead to unexpected issues down the line. Ensuring that isolators are maintained properly and adjusted as necessary is crucial for prolonging their lifespan and maintaining their effectiveness in vibration control. By avoiding these common mistakes, designers can enhance the functionality and reliability of their projects.

Monitoring and maintaining CTV chain isolators are crucial steps to ensure their longevity and optimal performance in various projects. Regular inspections should be scheduled to check for signs of wear, corrosion, or any potential damage to the isolators. It is essential to clean the components frequently to prevent the buildup of debris or contaminants, which could hinder their function. Monitoring the operational environment is also vital; factors such as temperature, humidity, and exposure to chemicals can significantly affect the performance and lifespan of the isolators. Implementing a routine maintenance schedule can help identify issues early, ensuring that the isolators operate safely and effectively.

In addition to routine inspections, proper documentation of the maintenance history is important. Keeping a detailed record of each inspection, maintenance activity, and any issues encountered provides valuable insights into the overall performance of the chain isolators. This documentation will also be beneficial in planning future maintenance activities and can help in training personnel. Furthermore, ensuring that the installation is compliant with industry standards can prevent unnecessary failures and extend the operational life of CTV chain isolators. By prioritizing monitoring and maintenance, one can maximize the efficiency and reliability of these critical components in any application.