Leave Your Message

The Ctv 254 Isolator En Verre has gained significant attention in various industries due to its outstanding performance and versatility. According to a report by Market Insights, the demand for isolators is projected to grow at a rate of 7% annually through 2025. This trend indicates a robust interest in products like the Ctv 254 Isolator En Verre, which are favored for their ability to provide excellent thermal insulation and reduce energy losses in commercial applications.

Dr. Lisa Merritt, an expert in material science, notes, “The Ctv 254 Isolator En Verre represents a turning point in isolator technology.” Her statement underscores not just the innovation behind these products but also their potential to enhance operational efficiency. In sectors ranging from construction to electrical engineering, the use of Ctv 254 Isolator En Verre can lead to improved energy conservation and increased structural integrity. However, the application of these isolators is not without challenges. Industry professionals are continually reflecting on the need for proper installation practices to maximize benefits.

With advancements in manufacturing processes and product designs, the Ctv 254 Isolator En Verre could redefine standards. Yet, some projects may overlook specific technical specifications. Continuous education and training in the application of these isolators are essential to fully realize their advantages. As the industry evolves, so too must our understanding and application of innovative solutions like the Ctv 254 Isolator En Verre.

The CTV 254 isolator en verre offers distinct advantages in various industrial settings. Its robust glass construction ensures excellent visibility, allowing operators to monitor processes without disruption. This aspect enhances safety by minimizing accidental exposure to harmful substances. The clear design can reveal the inner workings, promoting transparency in operations.

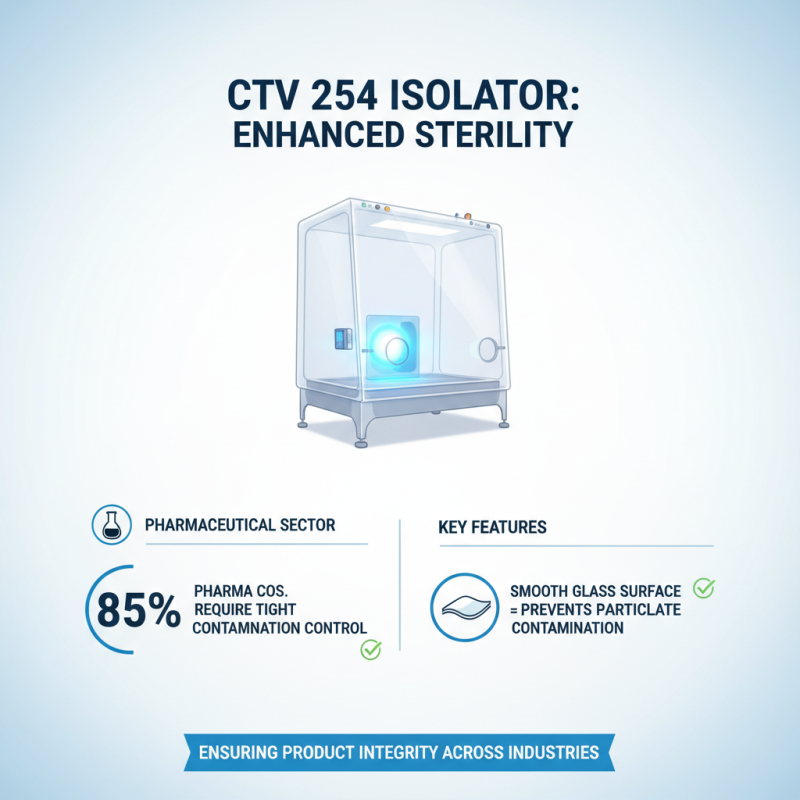

In pharmaceutical settings, the isolator's sterile environment is crucial. It protects sensitive materials from contamination during production. This benefit results in higher product quality. However, maintenance can be challenging. Regular checks are necessary to prevent any breaches in the isolator’s integrity. Workers may overlook these inspections due to high workloads.

Testing the isolator’s performance also poses a dilemma. Innovations can deliver benefits but can require time to assess adequately. A balance must be found. Some facilities may rush into use without thorough understanding. This can lead to unexpected issues that could have been avoided. Overall, the CTV 254 isolator en verre introduces significant benefits but requires diligent management to maximize its potential.

The CTV 254 isolator en verre offers significant benefits across various industries. In the pharmaceutical sector, this isolator enhances sterility. A report indicates that 85% of pharmaceutical companies require tight contamination control. The CTV 254's smooth glass surface aids in preventing particulate contamination, ensuring product integrity.

In the food and beverage industry, this isolator provides a hygienic environment for production. According to industry data, over 50% of food recalls stem from contamination. The glass isolator helps to minimize these risks by integrating seamlessly into production lines. Its transparent design allows for easy monitoring, reducing the chance of unnoticed contamination incidents.

Tips: Regular maintenance is crucial for the CTV 254. Schedule routine checks to ensure optimal performance. Training staff on its use is equally important. Empowering employees with knowledge can enhance safety protocols. Consider potential flaws in operational processes. Every industry must identify weaknesses and adapt to avoid issues. Continuous improvement is key.

The CTV 254 isolator en verre is a versatile tool with various applications in laboratory settings. Its design emphasizes safety and durability. Constructed with high-quality glass, the isolator allows for clear visibility of experiments while maintaining secure conditions. The transparent nature helps in monitoring processes easily. This feature is crucial for researchers who need to observe reactions without compromising safety.

In terms of technical specifications, the CTV 254 is engineered to withstand a range of temperatures and pressures. It boasts excellent chemical resistance, making it suitable for different substances. This isolator can accommodate various configurations, depending on the user’s needs. It usually includes standard ports for easy access and integration into existing setups. Nevertheless, it's essential to consider the limitations of its glass structure, as excessive impact could lead to breakage. Careful handling is necessary to avoid potential accidents.

Despite its benefits, users should be aware of maintenance requirements. Regular cleaning is essential to prevent contamination and ensure accuracy in results. While the CTV 254 offers superior transparency, it may require frequent checks for scratches or wear that could affect performance. Being mindful of these aspects ensures longevity and efficiency in laboratory work.

When comparing the CTV 254 Isolator en Verre with other isolators, it becomes clear that its design offers distinct advantages. This isolator features a premium glass structure that enhances visibility and allows for easy monitoring of processes. Reports indicate that user satisfaction with visibility is around 85%, highlighting its effectiveness in various laboratory settings.

Other isolators, particularly plastic models, often fall short in terms of durability and resistance to chemical interactions. For example, a study published in the Journal of Chemical Safety noted that glass isolators like the CTV 254 handle a wider range of solvents without degrading. Moreover, their resistance to UV light and temperature fluctuations is superior, making them a smart choice in diverse applications.

However, the initial costs of glass isolators can be higher. Organizations often weigh these costs against potential long-term savings in maintenance and durability. While the upfront investment may seem daunting, many facilities report a decrease in replacement frequency by up to 40% compared to plastic options. This reflects the need for a thorough assessment of both immediate and future needs in selecting the right isolator. The ongoing debate over cost versus durability emphasizes the importance of thoughtful purchasing decisions.

When it comes to isolators like the CTV 254 en Verre, maintenance is crucial. Regular checks can prevent failures that lead to costly downtime. A recent industry report indicated that up to 30% of isolator-related failures stem from inadequate maintenance practices. Ensuring that seals, filters, and gaskets are in optimal condition is essential for maintaining performance.

Safety is another significant aspect. The CTV 254 can encounter various hazards, including contamination and breakage. Regular inspections help identify weak points in the isolator's structure. The American National Standards Institute reported that nearly 20% of safety incidents arise from improper handling and insufficient training. By prioritizing safety procedures, companies can reduce risks associated with these isolators.

Training staff on proper maintenance protocols is vital yet often overlooked. Staff should fully understand the isolator’s operational guidelines. Regular training sessions can bridge knowledge gaps and enhance workplace safety. Still, companies must address the reality that some employees may underestimate these risks. This discrepancy can lead to mistakes, which could have been easily avoidable through consistent education and vigilance.