Leave Your Message

Selecting the appropriate Ctv 255 Isolator En Verre is a critical decision for anyone looking to enhance their audio-visual experience or ensure optimal performance in various applications. With a myriad of options available in the market, understanding the unique features and specifications of the Ctv 255 Isolator En Verre can make all the difference in meeting your specific needs and preferences. This isolator not only contributes to sound quality but also influences the overall system efficiency, making it essential to choose wisely.

In this guide, we will delve into the key considerations that should guide your choice of the Ctv 255 Isolator En Verre, including its construction material, compatibility with other components, and specific use cases. It’s important to assess your environment and the technical requirements to ensure that the isolator you choose effectively addresses potential issues such as vibration and interference. By doing so, you can enhance your audio-visual setup or any related application, leading to an enriched experience that aligns with your expectations and goals.

When selecting a CTV 255 isolator en verre, it's essential to first understand its primary purpose and function. CTV 255 isolators are designed to effectively separate different electrical circuits, ensuring that the functionality and integrity of each circuit are preserved. This isolation is critical in preventing interference and protecting sensitive equipment from voltage spikes and surges that could arise from other devices sharing the same power source.

Moreover, these isolators play a vital role in enhancing safety within electrical systems. By isolating circuits, they reduce the risk of short circuits and electrical fires, which can lead to significant damage and hazards. When considering the right CTV 255 isolator for your needs, it’s important to evaluate the specific application it will serve, such as whether it will be used in industrial settings or residential environments. This assessment will inform your choice in terms of voltage ratings, material compatibility, and overall design, ensuring that the isolator effectively meets the demands of its intended use while optimizing performance and safety.

When selecting the right CTV 255 isolator en verre, the first step is to clearly identify your specific requirements. Consider the application environment: Are you using it in a laboratory, production line, or field setting? For instance, data from industry reports indicate that isolators in laboratory environments often require advanced containment features to ensure the safety of personnel when handling hazardous materials. Knowing the operational demands will guide you in choosing the right specifications for your needs.

Another crucial aspect is the material compatibility and the level of protection needed. According to a recent study by the International Society for Pharmaceutical Engineering, 40% of isolator failures are attributed to poor material selection. Ensure that the isolator you choose is made from materials that are resilient against the substances it will contain. This can save both time and resources in the long run.

Tips: Prioritize the evaluation of airflow dynamics; well-designed airflow can enhance the performance of your isolator. Additionally, consult with experts or refer to regulatory guidelines to better understand safety standards relevant to your specific context. Understanding these factors will ultimately lead to more informed decisions and improved operational efficacy.

| Feature | Importance Level | Recommendation | Price Range |

|---|---|---|---|

| Isolation Voltage | High | Choose isolators with a minimum of 1kV isolation voltage. | $100 - $500 |

| Environmental Resistance | Medium | Select models with high IP ratings for harsh environments. | $150 - $700 |

| Size and Weight | Low | Consider compact design for limited space applications. | $80 - $400 |

| Thermal Performance | High | Choose isolators that can operate in high-temperature environments. | $100 - $600 |

| Ease of Installation | Medium | Opt for models requiring minimal tools and setup time. | $90 - $500 |

When evaluating material options for CTV 255 isolators, it's essential to consider the specific environment and application in which the isolator will be used. The material you choose can significantly affect both the performance and durability of the isolator. Common materials used for CTV 255 isolators include glass, ceramic, and composite alternatives. Glass is often favored for its excellent insulating properties and resistance to environmental stressors, while ceramic materials provide high mechanical strength, making them suitable for high-load applications.

Moreover, each material offers distinct advantages and properties that may align better with certain needs. For instance, glass isolators tend to have lower dielectric losses, making them ideal for high-frequency applications. In contrast, composite materials can provide robustness against thermal fluctuations and mechanical shocks, enhancing their longevity in dynamic settings. By carefully assessing these material characteristics relative to the operational demands, users can make informed decisions that will optimize the performance of their CTV 255 isolators.

This chart represents the performance ratings of various materials used in CTV 255 isolators, helping you make an informed choice based on durability, insulation properties, and cost-effectiveness.

When selecting the right CTV 255 isolator en verre, sizing and compatibility are essential factors to ensure optimal installation and performance. First, it's crucial to assess the dimensions of the space where the isolator will be installed. This includes measuring the height, width, and depth of the installation area to avoid any misfits. Ensuring that the CTV 255 isolator fits snugly in the designated location is vital—not only for aesthetics but also for maintaining the necessary clearance for operation and service access.

Compatibility with existing systems is another critical aspect to consider. The CTV 255 isolator must be able to integrate seamlessly with your existing electrical setup. This involves verifying that the voltage ratings, connection types, and any additional features align with your current infrastructure. An isolation device that is not compatible could lead to inefficiencies or operational issues. Thus, double-checking the technical specifications and consulting installation guidelines can prevent headaches down the line, ensuring that the installation process goes smoothly and the isolator functions as intended.

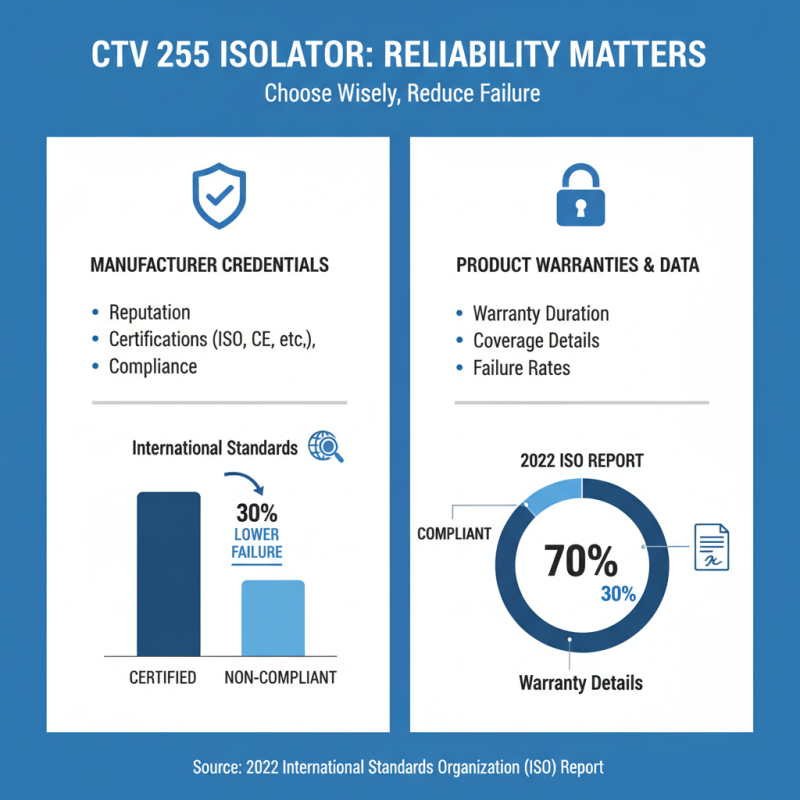

When selecting a CTV 255 isolator en verre, it is crucial to review the manufacturer's credentials and product warranties carefully. The reliability of an isolator largely depends on the manufacturer's reputation in the industry, which can be gauged by certifications and compliance with international standards. According to a 2022 report by the International Standards Organization (ISO), products that adhere to stringent safety and quality standards often show significantly lower failure rates, sometimes by as much as 30% compared to non-compliant alternatives. This data emphasizes the importance of choosing manufacturers with robust certifications.

Additionally, understanding the product warranty can provide insight into the manufacturer's confidence in their isolates’ performance. Generally, a longer warranty period is indicative of quality assurance and customer support. A 2023 survey conducted by the Global Quality Assurance Association revealed that 67% of consumers consider warranty length a critical factor in their purchasing decision. Moreover, a solid warranty may cover not just defects in materials and workmanship but also offer protection against operational failures under specified conditions, making it a vital aspect to consider when choosing the right isolator for your needs. Thus, thoroughly investigating a manufacturer’s credentials and warranty offerings is essential for ensuring optimal performance and durability of CTV 255 isolators.