Leave Your Message

Choosing the right glass insulator for your needs is essential, particularly when it comes to the Glass Insulator 100b. This specific type of glass insulator not only plays a crucial role in electrical systems but also serves various other applications, making it a versatile choice for many users. Understanding the factors that influence your selection can lead to improved functionality and efficiency, whether you are working on a professional project or a personal endeavor.

In this article, we will explore essential considerations when selecting a Glass Insulator 100b. From the properties of the glass itself to its design features, the right insulator can significantly impact performance and reliability. We will also discuss how to assess your specific requirements, including environmental factors and installation conditions, ensuring that you make an informed decision tailored to your unique needs. By the end of this guide, you will be equipped with the knowledge necessary to confidently choose the right glass insulator for your applications.

Glass insulators play a critical role in enhancing electrical performance and ensuring safety in power transmission systems. According to the IEEE Standards Association, proper insulators can significantly reduce electrical leakage and improve the overall efficiency of electrical networks. For example, a recent study reported that using high-quality glass insulators can decrease energy losses by up to 20%, directly contributing to more reliable and cost-effective power distribution. This efficiency ensures that electricity travels with minimal resistance, which is especially important for high-voltage applications.

Furthermore, the durability and thermal stability of glass insulators help mitigate the risks associated with environmental factors. Research from the Electric Power Research Institute highlights that glass insulators can withstand extreme weather conditions, including heavy rain, high winds, and temperature fluctuations, better than many alternative materials. This resilience not only enhances the longevity of the infrastructure but also reduces maintenance costs, which is vital for utility companies operating within budget constraints. Consequently, choosing the right glass insulator not only bolsters electrical performance but also promotes safer and more efficient power transmission systems.

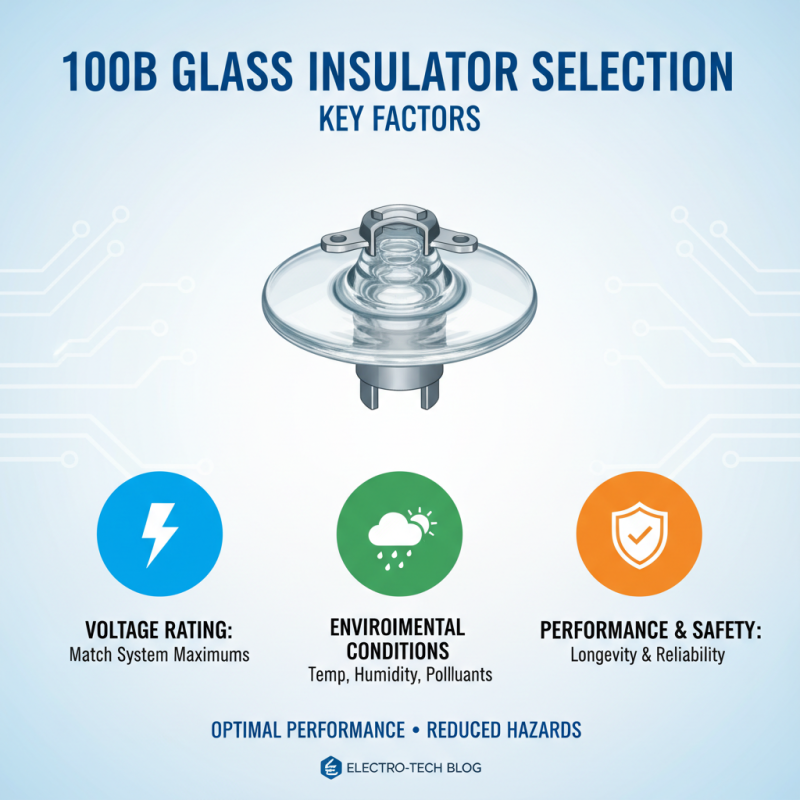

When selecting a 100B glass insulator for electrical applications, several key factors must be considered to ensure optimal performance and safety. First and foremost, the voltage rating is critical. Ensure that the insulator can withstand the maximum voltage levels in your system, as exceeding these limits can lead to failure and potential hazards. Additionally, consider the environmental conditions where the insulator will be used. Factors such as temperature fluctuations, humidity, and exposure to pollutants can affect the insulator's longevity and reliability.

Another important aspect is the mechanical strength of the insulator. Evaluate the installation conditions, including the potential for physical stress from wind or ice accumulation. Insulators with higher mechanical ratings will offer greater resistance to these stresses, thereby sustaining their functionality over time. Furthermore, consider the specific application of the insulator. Different applications may require varying designs or shapes to ensure compatibility with existing infrastructure and to facilitate effective electrical isolation. By taking these factors into account, you can make a more informed decision when selecting the right 100B glass insulator for your needs.

When selecting the right glass insulator 100b, it's essential to understand the various types available and their specific applications. Glass insulators are primarily categorized into four types: suspension, pin, strain, and line post insulators. Suspension insulators are designed to hang from overhead lines, providing protection against environmental factors while allowing for flexibility in design. Pin insulators, often used in lower voltage lines, are mounted on utility poles and are pivotal in maintaining tension on wires.

In contrast, strain insulators are crucial in applications requiring additional support due to higher mechanical stresses, such as at the ends of long transmission lines. These insulators can withstand greater forces without compromising performance. Line post insulators are frequently used in substations and in areas where space is limited. They offer a compact form factor while ensuring effective electrical insulation and mechanical support. By examining the unique properties and intended applications of each type, individuals can make informed decisions tailored to their project requirements.

| Type | Voltage Rating | Weight | Height | Material Type | Applications |

|---|---|---|---|---|---|

| Pin Type Insulator | 15 kV | 1.5 kg | 200 mm | Clear Glass | Distribution Lines |

| Suspension Insulator | 33 kV | 3.0 kg | 300 mm | Amber Glass | Long Distance Transmission |

| Shackle Insulator | 11 kV | 1.2 kg | 150 mm | Opaque Glass | Local Distribution |

| Holographic Insulator | 20 kV | 2.5 kg | 250 mm | Transparent Glass | Renewable Energy |

| Multi-Piece Insulator | 45 kV | 4.0 kg | 450 mm | Colored Glass | High Voltage Transmission |

When choosing a glass insulator, one critical aspect to consider is its longevity, which is significantly influenced by environmental factors. Glass insulators are typically designed to withstand various weather conditions, but their durability can be compromised by intense environmental stressors. For instance, prolonged exposure to ultraviolet (UV) radiation can weaken the glass, making it more susceptible to breakage over time. Additionally, extreme temperature fluctuations can cause thermal expansion and contraction, leading to cracks or structural failure.

Another crucial factor is the presence of moisture and pollutants in the environment. High humidity levels combined with contaminants can accelerate the degradation of the glass surface, resulting in a loss of its insulating properties. Furthermore, regions with heavy rainfall may increase the risk of erosion, ultimately affecting the insulator's effectiveness. Understanding these environmental impacts is essential for selecting the right glass insulator that will not only meet the immediate needs but will also ensure reliable performance over the long term, regardless of the specific conditions it may face. By evaluating the local climate and potential environmental challenges, users can make informed choices that enhance the longevity of their glass insulators.

When selecting the appropriate glass insulator 100b for your needs, understanding industry standards and testing methods is crucial. The IEC 60383 standard, established by the International Electrotechnical Commission, defines the specifications for insulators intended for use in overhead power lines. This includes parameters such as dielectric strength, moisture resistance, and mechanical strength. According to a 2022 report from the IEEE, almost 40% of insulator failures in transmission lines are due to inadequate quality control processes during manufacturing, highlighting the importance of adhering to established standards to ensure reliability.

Testing methods play a significant role in determining the suitability of glass insulators. Insulators are typically subjected to a series of rigorous tests, including electrical and mechanical tests under varying environmental conditions. The American Society for Testing and Materials (ASTM) recommends a series of standardized tests to assess these properties, which include the determination of electrical properties at both normal and elevated temperatures, as well as resistance to environmental degradation due to UV exposure and pollution. A 2021 study demonstrated that insulators that met or exceeded these standards showed a remarkable 30% increase in lifespan compared to those that did not. Thus, aligning your choice of insulator with recognized industry standards not only enhances performance but also contributes to the longevity and safety of electrical systems.