Leave Your Message

In today's world, pollution poses a serious threat to our environment. The search for clean energy solutions is more urgent than ever. One innovation in this space is the Anti-Pollution Glass Insulator. These insulators play a crucial role in reducing harmful emissions. They provide a sustainable option for energy transmission.

Using Anti-Pollution Glass Insulators can significantly lower the impact of pollutants. They are designed to resist dirt accumulation and environmental degradation. However, the effectiveness of these materials can vary based on their application. Some insulators may fall short in extreme weather conditions. This limitation calls for ongoing research and development.

While many are optimistic, we must also reflect on our choices. Are we investing enough in these technologies? The journey towards cleaner energy is complex and requires collaboration. Understanding the role of Anti-Pollution Glass Insulators is just the beginning. It is a step toward a more sustainable future.

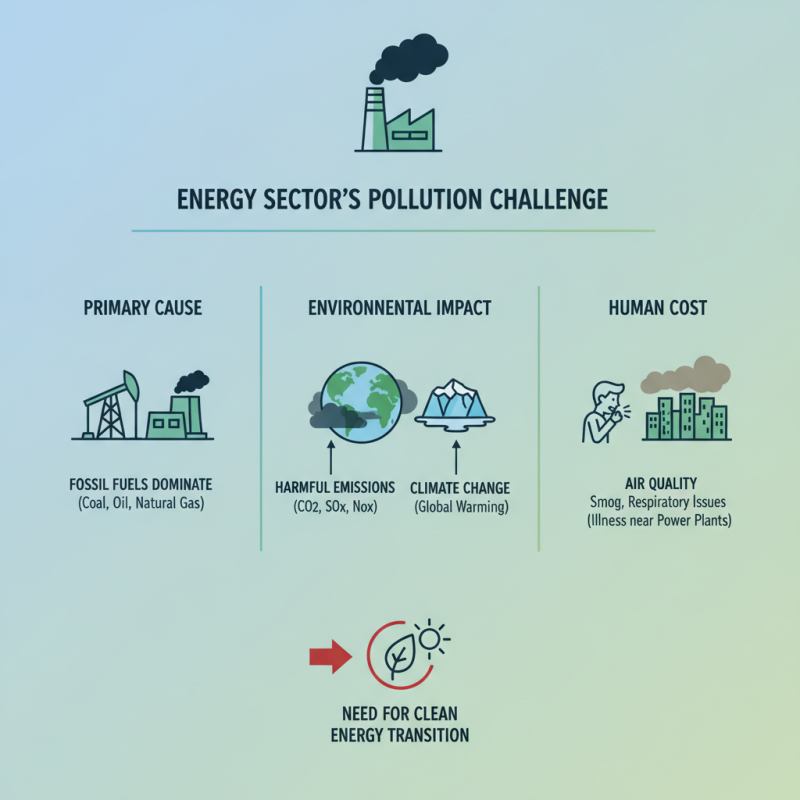

The energy sector faces significant pollution challenges. Fossil fuels dominate global energy production, leading to harmful emissions. These emissions affect air quality and contribute to climate change. Many communities struggle with health issues linked to pollution from power plants. Cities often see smog and respiratory problems rise during peak energy usage times.

Transitioning to clean energy is crucial. However, the current infrastructure often lags behind. Renewable energy sources, like solar and wind, are growing but not fast enough. Pollution prevention technologies in energy production can make a difference. Sadly, not all facilities use these technologies effectively. The push for cleaner solutions is sometimes hindered by costs and regulations.

Investing in better materials, like anti-pollution glass insulators, can play a role. They help improve efficiency and reduce waste. Yet, not every energy producer prioritizes these upgrades. The path to a cleaner energy future remains complex and requires ongoing commitment. More awareness and innovative solutions are necessary to tackle these pollution challenges.

Glass insulators play a crucial role in clean energy solutions. They ensure the durability of electrical systems by preventing pollution-related damage. A recent report from the International Energy Agency indicates that pollution can significantly impact the efficiency of energy transmission, leading to losses of up to 5%. Thus, utilizing high-quality glass insulators can mitigate these issues effectively.

Implementing glass insulators in renewable energy systems, like wind and solar installations, is essential. They resist weathering, which can degrade performance over time. For instance, insulators subjected to extreme temperatures or pollutants may require replacement more often, increasing maintenance costs. By investing in durable glass materials, energy providers can enhance system reliability.

Tips for selecting the right glass insulator include evaluating environmental conditions and installation settings. Look for insulators that meet industry standards for pollution resistance. Regular inspections are vital too; they help identify wear before it impacts efficiency. Remember, even small pollutants can accumulate and cause long-term damage. Prioritizing the right materials is not just about cost; it's about sustainable energy solutions.

Selecting the right anti-pollution glass insulators is crucial for enhancing clean energy solutions. Key criteria include environmental resistance, mechanical strength, and cost-effectiveness. Industry reports emphasize that insulators must withstand harsh weather. They should be resilient against industrial pollutants like sulfur dioxide and nitrogen oxides. Insulator failure can lead to significant energy losses.

The mechanical strength of the glass type chosen is essential. According to recent data, insulators can reduce maintenance costs by up to 30% when designed with high tensile strength. However, the production process and materials used can affect sustainability. Investing in eco-friendly manufacturing techniques is vital. It ensures a higher lifespan and reduces overall carbon footprints.

Another critical factor to consider is the insulator's electrical performance. Research has shown that optimal electrical insulation decreases the risk of power outages. However, some products may not perform as expected under specific conditions. This inconsistency can lead to unreliable energy systems. Therefore, thorough testing and validation are necessary for proper selection.

The demand for clean energy solutions continues to rise. One way to address pollution is through the use of anti-pollution glass insulators. These specialized insulators are crucial in minimizing the environmental impact of electrical systems. Reports indicate that dirty insulators can increase power loss by up to 30%. This highlights the importance of choosing the right materials for energy infrastructure.

Anti-pollution glass insulators possess features that enhance their durability and effectiveness. They resist dirt accumulation, preventing electrical flashovers. Research shows that insulators made from high-quality glass can withstand harsh weather conditions better than traditional materials. This longevity means fewer replacements, which saves costs and reduces waste.

Here are some tips for selecting the right anti-pollution glass insulators:

- Look for high mechanical strength ratings.

- Ensure compliance with environmental standards.

- Check for low leakage current ratings.

Emphasizing these characteristics can significantly improve the overall performance of energy systems. However, some installations may still experience issues due to improper maintenance. It’s vital to regularly assess insulator condition. This proactive approach can prevent larger failures and unexpected downtime. Balancing innovation with responsible practices can lead to true progress in clean energy efforts.

The demand for clean energy solutions is rapidly growing. As air pollution continues to be a pressing concern, anti-pollution glass insulators emerge as a vital component. These insulators not only enhance energy transmission but also contribute to environmental protection. Upcoming trends suggest advancements in materials and designs, improving their efficiency.

Innovative technologies are expected to make these glass insulators more effective. Enhanced coatings could deflect pollutants and improve performance. Integrating self-cleaning properties would reduce maintenance and enhance lifespan. The future also points to the use of recycled materials, promoting sustainability. However, challenges in production and cost still remain.

**Tips:**

Choose designs that combine aesthetic value with functionality. Different environments may require specific features, so assess your needs carefully. Not all options will be perfect; learning from past mistakes is crucial for progress. Expect to adapt as technologies evolve. Stay updated on new materials to ensure you make informed choices.