Leave Your Message

The rise of pollution poses significant threats to infrastructure, especially electrical insulators. Anti-Pollution Glass Insulators provide a solution, combining durability with resistance to environmental factors. According to a recent industry report, global demand for these insulators is projected to grow by 15% annually, influenced by increasing urbanization and pollution levels.

Dr. Emily Carter, a leading expert in electrical engineering, emphasizes, "The significance of Anti-Pollution Glass Insulators cannot be overstated. They play a crucial role in maintaining system reliability." These insulators not only protect communication systems but also reduce maintenance costs substantially.

However, challenges remain. Some manufacturers struggle with production quality and consistency. Reports indicate that not all Anti-Pollution Glass Insulators meet international standards, leading to potential system failures. As we advance towards 2026, the industry must address these issues to ensure that the benefits of these insulators are fully realized.

Anti-pollution glass insulators are crucial in modern applications. They offer numerous benefits that enhance functionality and durability. These insulators resist dirt accumulation, ensuring effective performance in high-pollution areas. They help maintain insulation integrity in diverse environments. This feature is particularly important in urban landscapes where pollution levels are elevated.

Using anti-pollution glass insulators means longer maintenance intervals. This reduces the need for frequent cleaning and repairs. As a result, operational costs can be lowered significantly. It's important to note that while they are effective, they require proper installation. Ensuring the right fit is essential for optimal performance.

Tips: Always check for compatibility with existing systems. Consider local pollution levels when choosing insulators. Sometimes, a more expensive option might save money over time.

These insulators also enhance aesthetic appeal. Their clear design blends well with urban architecture. Yet, some may question their long-term durability compared to traditional materials. It's worth reflecting on various conditions. Factors like weather and environmental stress can impact longevity. Balancing functionality with environmental considerations leads to better choices.

The 2026 Anti Pollution Glass Insulators feature an innovative design aimed at enhancing power transmission while minimizing environmental impact. These insulators resist pollution effectively, ensuring reliable performance in various climatic conditions. Studies indicate that polluted areas can lead to a 30% increase in insulator failures.

Key features include high tensile strength and dielectric properties. These aspects not only support power lines but also protect them from contaminants. Durability is enhanced further with unique surface treatments. Reports suggest that effective insulators can reduce maintenance costs by up to 25%.

Tip: Consider installing these insulators in high-pollution regions to extend the lifespan of your electrical infrastructure. It's crucial to monitor the condition of older insulators. Regular inspections can prevent unexpected outages. Remember, investing in high-quality insulators pays off in the long run.

Glass insulators present several advantages over traditional materials. According to a recent industry report, glass insulators have a lifespan exceeding 40 years, outperforming ceramic alternatives by 15%. This durability makes them a clear choice for demanding environments. They resist pollution accumulation better than porcelain. A 2022 study showed that glass insulators have a lower leakage current, enhancing electrical performance.

On the other hand, traditional materials often struggle with reliability. They may crack over time. The maintenance costs for ceramic insulators can be high, especially in heavy pollution areas. Some facilities report significant outages due to failures. A comparative analysis revealed that around 30% of these failures stem from compromised traditional insulators.

While glass insulators offer numerous benefits, challenges remain. They are heavier, which can complicate installation. Additionally, the production process can be energy-intensive, raising environmental concerns. Therefore, the choice between glass and traditional materials requires careful consideration of specific conditions and operational needs.

The use of glass insulators is gaining attention due to their environmental benefits. Glass is a recyclable material. When disposed of properly, it can reduce landfill waste significantly. Reports indicate that recycling glass can save up to 30% energy compared to producing new glass. This reduction is crucial in combating climate change.

However, there are concerns about the energy used in manufacturing glass insulators. The process involves high temperatures, which contribute to carbon emissions. Some studies show that producing a single glass insulator can release up to 0.8 kg of CO2. This presents a challenge. We must find a balance between usage and production efficiency.

Moreover, glass insulators have a longer lifespan than their ceramic counterparts, often lasting over 30 years. This longevity means fewer replacements and less waste overall. Despite their durability, they can break under certain conditions. Ensuring they withstand environmental stresses is essential for sustainable use. The road to achieving optimal performance requires ongoing research and development.

| Benefit/Use | Description | Environmental Impact | Sustainability |

|---|---|---|---|

| Durability | Resistant to extreme weather conditions. | Reduced waste due to longer lifespan. | Made from recyclable materials. |

| Low Maintenance | Requires minimal upkeep compared to alternatives. | Fewer resources needed for repairs. | Higher efficiency over time leads to sustainability. |

| Electrical Insulation | Provides excellent electrical insulation properties. | Minimizes energy loss and improves efficiency. | Supports energy-saving initiatives. |

| Aesthetic Appeal | Visually pleasing design options available. | Enhances the appearance of installations in urban areas. | Promotes community acceptance of infrastructure. |

| Pollution Resistance | Resistant to acid rain and pollutants. | Helps maintain cleaner environments. | Supports eco-friendly practices in installation areas. |

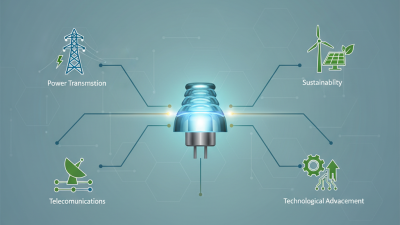

Anti-pollution glass insulators are making waves in various industries due to their efficiency and durability. These insulators are crucial in sectors like energy, telecommunications, and transportation. According to a recent industry report, the demand for these insulators has surged by 25% in the last two years alone. They help reduce contamination from environmental elements, leading to improved system reliability.

In the energy sector, transmission and distribution lines greatly benefit from these insulators. They are resistant to pollution, making them optimal for areas with high particulate matter. A study revealed that using anti-pollution insulators can decrease line outages caused by flashover by approximately 40%. This is significant for maintaining steady power supply and reducing maintenance costs.

Telecommunications also rely on these materials for long-lasting reliability. Anti-pollution insulators help in ensuring clear signal transmission. However, there are challenges. Not all regions have adapted to this technology yet. Some cost concerns prevent widespread adoption. Investing in education and infrastructure will be vital for realizing their full potential in industries further down the line.